NEWS

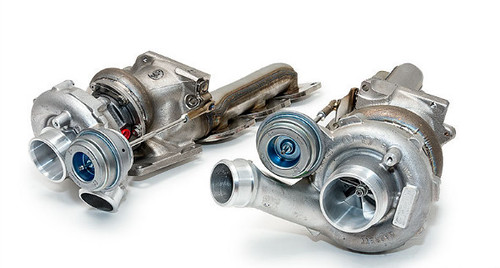

Twin-turbo or bi-turbo have two separate turbochargers operating in either a sequence or in parallel. In a parallel configuration, both turbochargers are fed one-half of the engine’s exhaust. In a sequential setup, one turbocharger runs at low speeds and the second turns on at a predetermined engine speed or load. Sequential turbochargers further reduce turbo lag but require an intricate set of pipes to properly feed both turbochargers.

twin-turbos employ a small turbocharger at low speeds and a large one at higher speeds. They are connected in a series so that boost pressure from one turbocharger is multiplied by another, hence the name "2-stage." The distribution of exhaust gas is continuously variable, so the transition from using the small turbocharger to the large one can be done incrementally. Twin turbochargers are primarily used in Diesel engines.

Bi-turbo only the smaller turbocharger works at low speed, providing high torque at 1,500–1,700 rpm. Both turbochargers operate together in mid-range, with the larger one pre-compressing the air, which the smaller one further compresses. A bypass valve regulates the exhaust flow to each turbocharger. At higher speed (2,500 to 3,000 RPM) only the larger turbocharger runs.

Smaller turbochargers have less turbo lag than larger ones, so often two small turbochargers are used instead of one large one. This configuration is popular in engines over 2,500 CCs and in V-shape or boxer engines.

Do you think this blog helpful for you? If you want to learn about more, follow us and we will update more knowledge for you.